Thanks

shim swap

-

DevonCbx

- Forum Regular

- Posts: 155

- Joined: Fri Jan 12, 2007 7:39 pm

- Location: Edmonton, Alberta, Canada

- Location: Edmonton, Alberta, Canada

shim swap

Several years ago I assembled my 79 CBX out of 3 CBX's. I learned alot during the restore. Though I really donnot know much about the engine internally. What I am wondering is why do shims need to sometimes be replaced? Is it to do with the cam lobes wearing or is it to do with the springs changing tension? How does the feeler gauge slide under the lobe while the lobe is pressing down on the shim? Or am I not looking at the procedure the right way? Is the feeler gauge slid under the pointy end of the lobe, or the rounded end?

Thanks

Thanks

-

ericfreeman

- Forum Regular

- Posts: 185

- Joined: Sun May 10, 2009 12:45 am

- Location: Point Roberts, WA

- Location: Point Roberts, Washington, USA

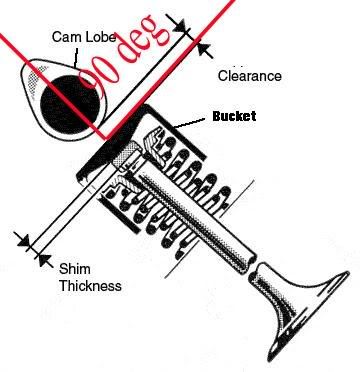

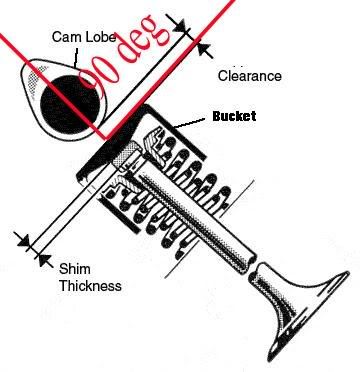

You measure the clearance between the shim and the rounded part of the cam lobe where no valve lift occurs. Clearances can change over time, usually as the valve and seat wear, allowing the valve to sit deeper in the head. This reduces the valve/cam clearance and you don't notice it since it's not making any noise. Unlike when valves are too loose and they tick/click when running. Fortunately, once the clearances are set they usually stay in spec for a long time.

Eric

Eric

- alimey4u2

- ICOA Web Video Director

- Posts: 4618

- Joined: Fri Aug 11, 2006 1:03 pm

- Location: Uphill, WsM, United Kingdom

-

EMS

- ICOA Member

- Posts: 9378

- Joined: Wed Mar 05, 2003 7:55 am

- Location: North East OH, ICOA 3904

-

broook

- Power Poster

- Posts: 493

- Joined: Tue Mar 11, 2003 9:14 pm

- Location: Newfoundland

- Contact:

Hate to jump in here Larry but shouldn`t that be 180deg like Mikes pic??alimey4u2 wrote:To add to Erics excellent advice, the feeler should be a drag fit, not too tight & obviously not too loose... The "pointy bit" should be pointing away from the shim at 90 degrees. Not to the vertical as the valves are at an angle....

If not I have been doing it wrong for over 50 years.

- alimey4u2

- ICOA Web Video Director

- Posts: 4618

- Joined: Fri Aug 11, 2006 1:03 pm

- Location: Uphill, WsM, United Kingdom

Broook you are correct in saying 180 deg rotation but if you measure the angle to the plane ( shim) it's 90 degrees.. Just a matter of wording I think.

Last edited by alimey4u2 on Fri Apr 16, 2010 9:18 am, edited 1 time in total.

ICOA # 656

-

broook

- Power Poster

- Posts: 493

- Joined: Tue Mar 11, 2003 9:14 pm

- Location: Newfoundland

- Contact:

- alimey4u2

- ICOA Web Video Director

- Posts: 4618

- Joined: Fri Aug 11, 2006 1:03 pm

- Location: Uphill, WsM, United Kingdom

To help Duane understand, there are sometimes "quieting ramps" on the base of the cam profile. These gently release the valve on closure & also gently open the valves. The reason you measure with the cam lobe at 90 degrees to the shim is to remove their effect when doing your measurements...

And Mike, I got one back for all those times you've proven me to be wrong...

And Mike, I got one back for all those times you've proven me to be wrong...

ICOA # 656

-

broook

- Power Poster

- Posts: 493

- Joined: Tue Mar 11, 2003 9:14 pm

- Location: Newfoundland

- Contact:

-

broook

- Power Poster

- Posts: 493

- Joined: Tue Mar 11, 2003 9:14 pm

- Location: Newfoundland

- Contact: