Stainless fork tube pinch bolts source? '79 headlight mod...

-

BayArchitect

- Forum Regular

- Posts: 63

- Joined: Wed Oct 11, 2006 7:10 pm

- Location: Los Gatos, CA

- Location: Los Gatos, CA

Stainless fork tube pinch bolts source? '79 headlight mod...

I polished the triple trees on my '81 CBX, and want to use stainless socket head bolts to put them back together. Does anyone know a supplier for 7mm socket head stainless bolts for the upper tree? I could drill these out to 8mm, but I'm not sure if this will cause a problem. Any thoughts? I have a spare tree, so the mod can be reversed.

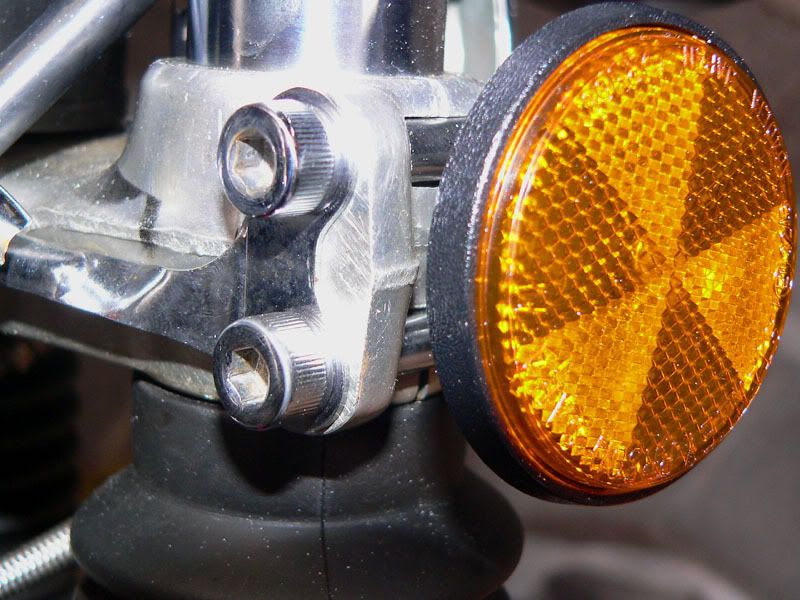

Also, here's a tip for anyone removing their '81 fairing and replacing it with a '79 headlight assembly: I replaced the two 8mm bolts which hold the instruments in place with a stainless 8mm bolt, 40mm long. I turned down the last 22mm of the bolt to 6mm and threaded it to leave a 10mm shoulder, then threaded the 8mm segment up to leave a 5mm shoulder at the head. This bolt provides a secure, rattle-free system for securing both the instruments and the headlight frame, while allowing the modification to be easily reversed to stock. The recommended modification for this, as described in the "175 How-To Articles" manual, didn't make much sense to me.

Also, here's a tip for anyone removing their '81 fairing and replacing it with a '79 headlight assembly: I replaced the two 8mm bolts which hold the instruments in place with a stainless 8mm bolt, 40mm long. I turned down the last 22mm of the bolt to 6mm and threaded it to leave a 10mm shoulder, then threaded the 8mm segment up to leave a 5mm shoulder at the head. This bolt provides a secure, rattle-free system for securing both the instruments and the headlight frame, while allowing the modification to be easily reversed to stock. The recommended modification for this, as described in the "175 How-To Articles" manual, didn't make much sense to me.

- alimey4u2

- ICOA Web Video Director

- Posts: 5093

- Joined: Fri Aug 11, 2006 1:03 pm

- Location: Uphill, WsM, United Kingdom

Re: Stainless fork tube pinch bolts source? '79 headlight mo

BayArchitect wrote:I polished the triple trees on my '81 CBX, and want to use stainless socket head bolts to put them back together. Does anyone know a supplier for 7mm socket head stainless bolts for the upper tree? I could drill these out to 8mm, but I'm not sure if this will cause a problem. Any thoughts? I have a spare tree, so the mod can be reversed.

I have reservations about using stainless bolts on vital services. I have found that they tend to "creep".....

I think I'm being overcautious here but needless to say, I have to say it..

If you do use them ( http://www.mcmaster.com is a supplier) I would keep a routine check on them using a torque wrench.......

-

EMS

- ICOA Member

- Posts: 10151

- Joined: Wed Mar 05, 2003 7:55 am

- Location: North East OH, ICOA 3904

A 7mm cylindrical Allen head bolt is not a standard metric item. The nominal head diameter for M6 is 10mm and for M8 it is 13mm. The Allen key size for the 6mm bolt is 5mm and for the 8mm bolt is 6mm.

There is little room for anything in between and I guess the 7mm bolt is a custom made oddity borne out of necessity, when a 6mm is too small and an 8mm is either too large and/or a 13mm head doesn't fit the space

There is little room for anything in between and I guess the 7mm bolt is a custom made oddity borne out of necessity, when a 6mm is too small and an 8mm is either too large and/or a 13mm head doesn't fit the space

-

BayArchitect

- Forum Regular

- Posts: 63

- Joined: Wed Oct 11, 2006 7:10 pm

- Location: Los Gatos, CA

- Location: Los Gatos, CA

Thanks for the tip, but as for drilling to 8mm...

Thanks for the McMaster suggestion, but they don't have lock nuts or acorns in M7--only hex nuts--not acceptable in this location.

Does anyone see a problem drilling the tree out and using 8mm bolts? I can't see any problems, but better to ask before drilling. I don't see any case-hardening used, or mechanical interference...

Does anyone see a problem drilling the tree out and using 8mm bolts? I can't see any problems, but better to ask before drilling. I don't see any case-hardening used, or mechanical interference...

-

Chris

- Amazing Poster

- Posts: 1299

- Joined: Fri Jan 16, 2004 2:00 pm

- cbxtacy

- Posting God

- Posts: 2543

- Joined: Sun Aug 29, 2004 4:22 am

- Location: San Diego, California, USA

- Location: San Diego, California, USA

-

BayArchitect

- Forum Regular

- Posts: 63

- Joined: Wed Oct 11, 2006 7:10 pm

- Location: Los Gatos, CA

- Location: Los Gatos, CA

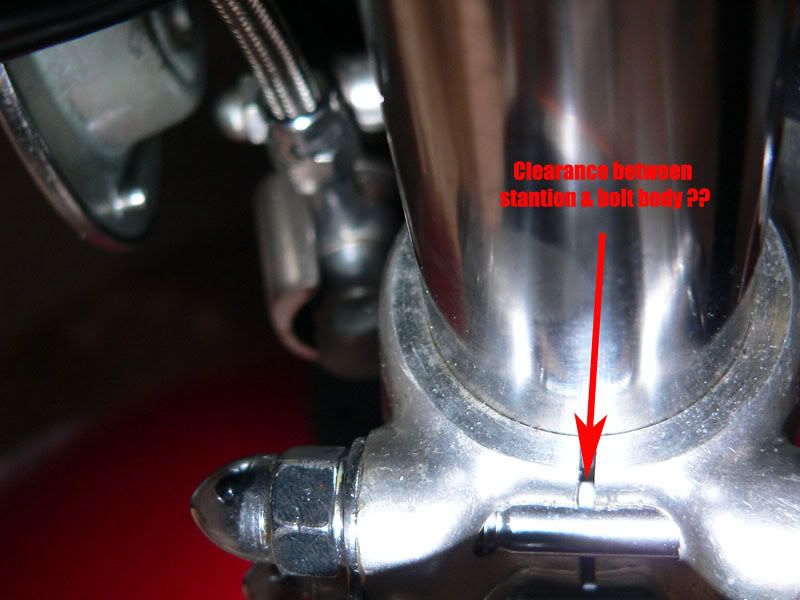

Photo shows lower tree, but it's the upper tree that has 7mm

Hi again: Thanks for the replies and the photo, but the lower tree already has 8mm bolts. It's the upper tree that has 7mm bolts--that's the one I'm thinking about drilling. Regards, Leon

- alimey4u2

- ICOA Web Video Director

- Posts: 5093

- Joined: Fri Aug 11, 2006 1:03 pm

- Location: Uphill, WsM, United Kingdom

Re: Photo shows lower tree, but it's the upper tree that has

BayArchitect wrote:Hi again: Thanks for the replies and the photo, but the lower tree already has 8mm bolts. It's the upper tree that has 7mm bolts--that's the one I'm thinking about drilling. Regards, Leon

Dooh !!......

-

BayArchitect

- Forum Regular

- Posts: 63

- Joined: Wed Oct 11, 2006 7:10 pm

- Location: Los Gatos, CA

- Location: Los Gatos, CA

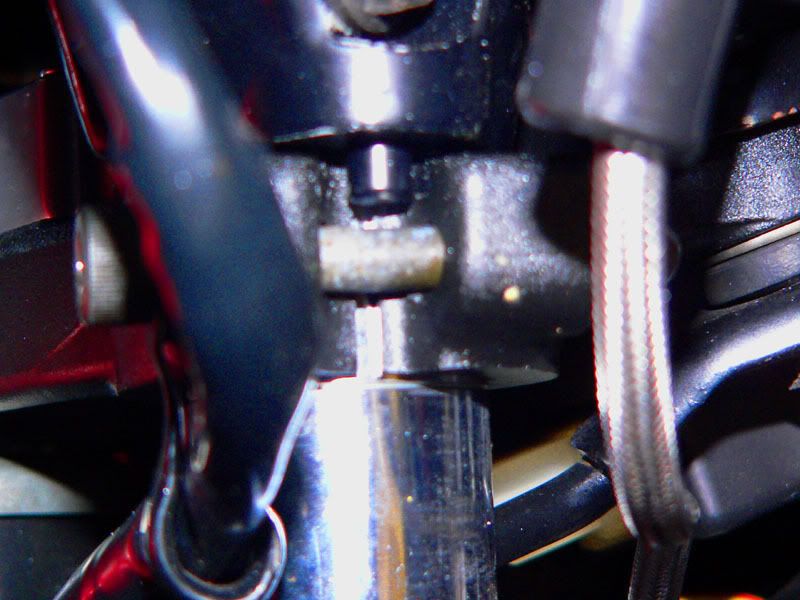

Final Report: SS 8mm bolts at upper tree...

I drilled out the upper tree and installed 8mm SS socket head cap screws. They look great, but more important, I believe no safety was compromised. The holes are already practically the same size as the 8mm bolts. Just the slightest (SLIGHTEST) enlargement makes it work. Don't do this with a hand-drill. Alignment is critical, because you don't want to remove ANY more material than absolutely necessary. Use a good drill press or lathe. Also, I recommend Bostik Never-Seez Pure Nickel Special on all SS threads. I use small foam-tipped disposable applicators (the kind with the wood stick), sold by Griots Garage, et al.